Wire guidance technology is transforming warehouse operations by improving efficiency and precision. But is your facility ready for this upgrade? Here are five signs your warehouse is a strong candidate for wire guidance implementation.

1. High Volume of Repetitive Tasks

If your warehouse has a consistent flow of repetitive movements, such as picking, loading, and stacking, wire guidance can streamline these operations. It automates navigation, reducing the time spent on manual tasks and increasing productivity.

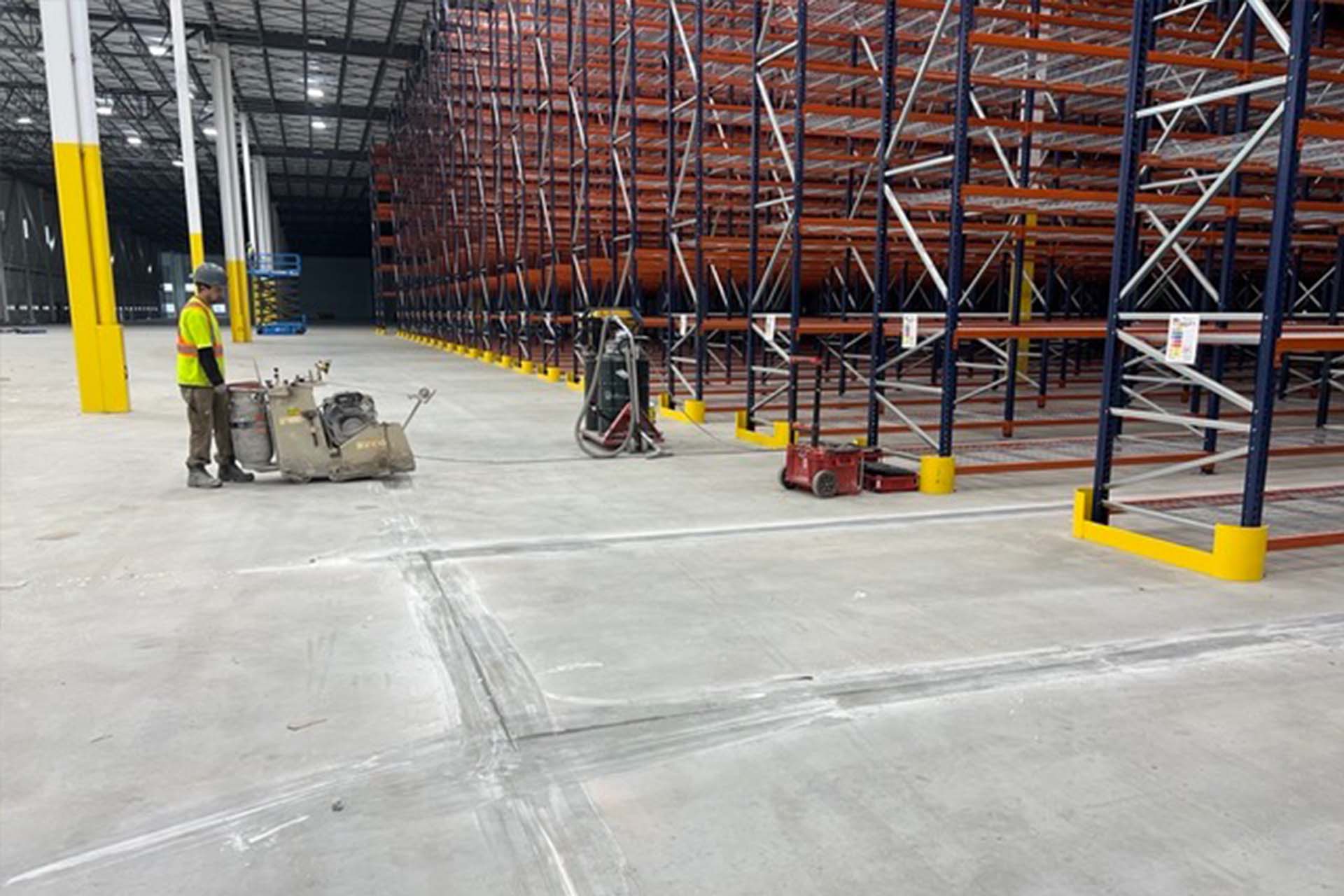

2. Tight Aisle Spaces

Warehouses with narrow aisles often face challenges in manual navigation. Wire guidance ensures precise vehicle alignment, allowing forklifts and equipment to move smoothly in tight spaces without the risk of damage or accidents.

3. Frequent Traffic Congestion

Heavy equipment traffic can lead to delays and safety concerns. Wire guidance organizes equipment movement, minimizing bottlenecks and optimizing floor space for seamless operations.

4. Growing Focus on Accuracy and Safety

If your facility is prioritizing safety and accuracy, wire guidance is an ideal solution. The technology reduces human error, ensuring precise navigation and protecting both equipment and workers.

5. Plans for Long-Term Growth

As your warehouse scales, efficiency and organization become crucial. Wire guidance supports scalability by handling increased workloads while maintaining consistent performance.

Conclusion

Wire guidance is a game-changer for warehouses looking to enhance efficiency and safety. If your facility exhibits these signs, it might be time to consider this technology. Investing in wire guidance can future-proof your operations, giving you a competitive edge.